We offer this extensive range of specialist stainless steel seamless elliptical oval tubes that have been developed specifically for industrial purposes.

We offer these high quality products to any part of the world.

Applications:

- HVAC

- Refrigeration

- Engine Cooling (Automotive)

- Oil Production

- Power Generation

Sizes available in both 304 and 316L

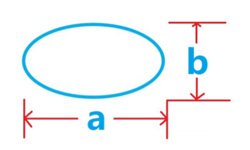

Stainless Steel Elliptical Oval Tubes

- 20 x 10 x 1.0mm – 1.5mm

- 24 x 13 x 1.0mm – 1.5mm

- 22 x 15 x 1.0mm – 2.0mm

- 25 x 14 x 1.0mm – 2.0mm

- 30 x 10 x 1.0mm – 2.0mm

- 30 x 15 x 1.0mm – 2.0mm

- 33 x 13 x 1.0mm – 2.0mm

- 30 x 20 x 1.0mm – 2.0mm

- 38 x 15 x 1.0mm – 2.0mm

- 40 x 20 x 1.0mm – 2.0mm

- 38 x 25 x 1.0mm – 2.0mm

- 41 x 26 x 1.0mm – 2.0mm

- 45 x 30 x 2.0mm

- 45 x 28 x 2.0mm

- 49 x 25 x 2.0mm

- 50 x 20 x 2.0mm

- 50 x 30 x 2.0mm

- 60 x 20 x 2.0mm

- 54 x 34 x 2.0mm – 3.0mm

- 60 x 30 x 2.0mm – 3.0mm

- 65 x 36 x 2.0mm – 3.0mm

- 60 x 40 x 2.0mm – 3.0mm

- 58 x 43 x 2.0mm – 3.0mm

- 80 x 25 x 2.0mm – 3.0mm

- 79.6 x 33.8 x 2.0mm – 4.0mm

- 80 x 40 x 2.0mm – 4.0mm

- 76 x 48 x 2.0mm – 4.0mm

- 93 x 55 x 2.0mm – 4.0mm

- 90 x 60 x 2.0mm – 4.0mm

- 100 x 46 x 2.0mm – 4.0mm

- 110 x 40 x 2.0mm – 4.0mm

- 120 x 48 x 3.0mm – 5.0mm

- 120 x 50 x 3.0mm – 5.0mm

- 115 x 58 x 3.0mm – 5.0mm

- 105 x 70 x 3.0mm – 5.0mm

- 90 x 50 x 3.0mm – 5.0mm

- 113 x 74 x 3.0mm – 6.0mm

- 150 x 50 x 3.0mm – 6.0mm

- 131 x 68 x 3.0mm – 6.0mm

- 120 x 80 x 3.0mm – 6.0mm

- 141 x 70 x 3.0mm – 6.0mm

- 150 x 60 x 3.0mm – 6.0mm

- 150 x 70 x 3.0mm – 6.0mm

- 160 x 72 x 3.0mm – 6.0mm

- 180 x 75 x 3.0mm – 6.0mm

- 180 x 95 x 3.0mm – 6.0mm

- 203 x 107 x 3.0mm – 6.0mm

- 215 x 113 x 3.0mm – 6.0mm

- 300 x 125 x 4.0mm – 6.0mm

Please note that Minimum Order Quantities may apply on Mill Production.

Item Name: Stainless Steel Seamless Elliptical Oval Tubes

Standard: ASTM A312

Grade of Material: AISI 201, 304, 316L, etc.

Certificate: ISO 9001: 2008

Dimension: 20 mm x 10 mm – 300 mm x 125 mm (See Range Below)

Wall Thickness: 1.0 mm – 6.0 mm

Surface: Polished 320 G, 400 G, 600 G; Hairline; Descaled.

Length: 10 mm – 12000 mm

Packing: PVC Bag, Weaving Bag, Wooden or Steel Case, etc.

Application: Construction & Building, Heat Exchange, etc.

Chemical Composition

| Grade of Material | C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| AISI 201 | ≤0.15 | ≤1.00 | 5.50~7.50 | ≤0.060 | ≤0.03 | 1.00 ~1.50 | 13.50~15.00 | \ |

| AISI 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~11.00 | 18.00~20.00 | \ |

| AISI 316L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

Mechanical Property

| Grade of Material | Elongation (%) | (Rm) N/m m³ | Yield Strength (Rp) 0.2%N/m m³ | Hardness (HV) |

|---|---|---|---|---|

| AISI 201 | ≥35 | ≥515 | ≥205 | ≤200 |

| AISI 304 | ≥35 | ≥515 | ≥205 | ≤200 |

| AISI 316L | ≥35 | ≥485 | ≥170 | ≤200 |

Our Advantages

- High-quality products as per certificate ISO 9001: 2008.

- Good services to satisfy you.

- Timely delivery for your orders.

- Samples are available as per your request.

Minimum mill production quantities may apply.